The solution for the fully-automatic fusion process- Highest precision and quality for highest analytical performance

Use

Preparation of fused beads (34 mm diameter)

Material

Different oxidic sample material,e.g., cement, slag, ores, ferroalloys (feed size 200µm)

Operation mode

Automatic

Compact design, safe operation, reliable results

All components of the machine are accommodated in a compact machine stand. The integrated robot performs all transport functions within the machine, reliably and quietly. Therefore, the HAG-HF is ideal for use in labs. The high-frequency heating technology is safe and economical. The fusion process can be reliably and economically controlled. The machine is fully automatic and even monitors itself during operation. Inferior castings are detected and discarded together with the holding ring. A new ring is inserted and the respective processing step is then repeated. Dirty crucibles and casting dishes are cleaned in the ultrasonic cleaning bath and then dried. This enables the HAG-HF to significantly reduce the times for sample processing and provides for trouble-free operation without the need for operating personnel. In automatic and magazine mode the machine works around the clock fully automatic and reliable processing.

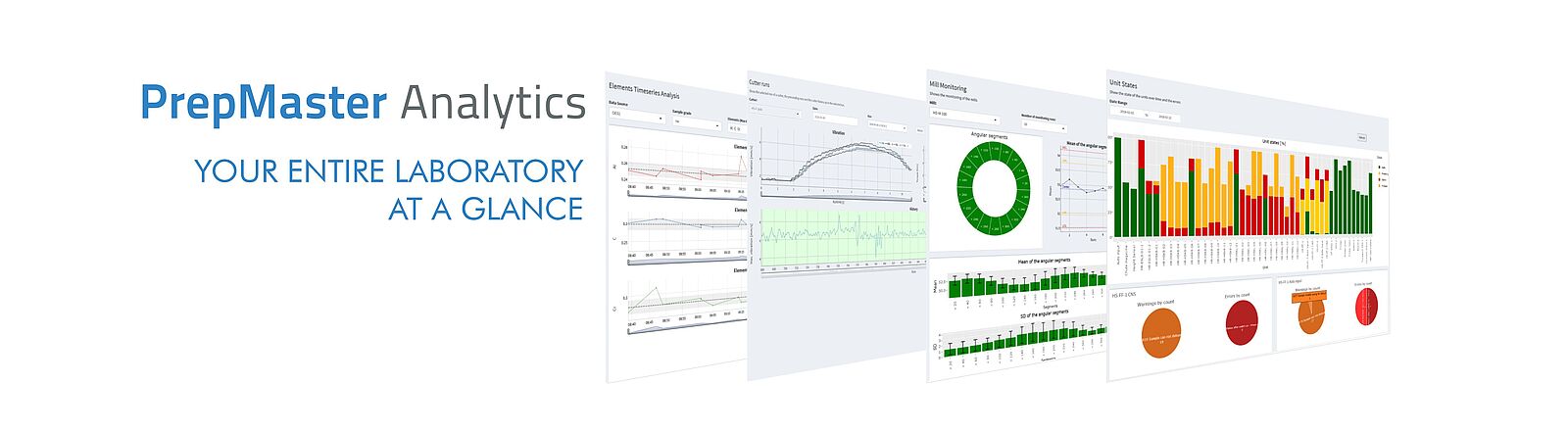

Automatic computer process control

All processing procedures in the HAG-HF are controlled and monitored by a computer. The software regulates the temperature during the melting process and controls the cleaning of the crucibles and casting dishes, in addition to managing the samples. A graphic diagram on the monitor continuously provides information on the status of the melting process.

The sample material can be transferred to the HAG-HF via transport belt, a pneumatic tube system or robots. The automatic mode can be interrupted for the input of single or priority samples. These take priority over other samples. After they are processed, normal operation is automatically resumed. The integrated scale is precise down to 0,1mg. It is protected against air currents and vibrations.

The crucibles are oscillated in a circular movement during the melting process. This guarantees thorough mixing of the molten mass. The molten material is poured into a preheated casting dish. Afterwards, it first cools to the ambient temperature. After solidifying, the casting dish is blown with precisely dosed compressed air from below until the sample is released from the crucible.

The vacuum suction unit transfers only intact castings to the transport systems and the spectrometer. A sensor detects crystallized or broken castings and ensures that they are discarded.

Process surveillance

To prevent contamination of the analysis surface during transport, the castings are not transferred directly to the transport system. With the side to be analyzed facing downward, they are placed on the edges of a holding ring. This ensures that only intact castings make it to the analysis equipment.

Three crucibles or casting dishes can be cleaned simultaneously in the ultrasonic cleaning station. Each crucible and each casting dish run through a separated cleaning cycle defined by parameters. The crucibles and casting dishes are then immediately available for further fusion processes. The cleaning fluid in the ultrasonic cleaning bath is automatically renewed at freely selectable intervals.