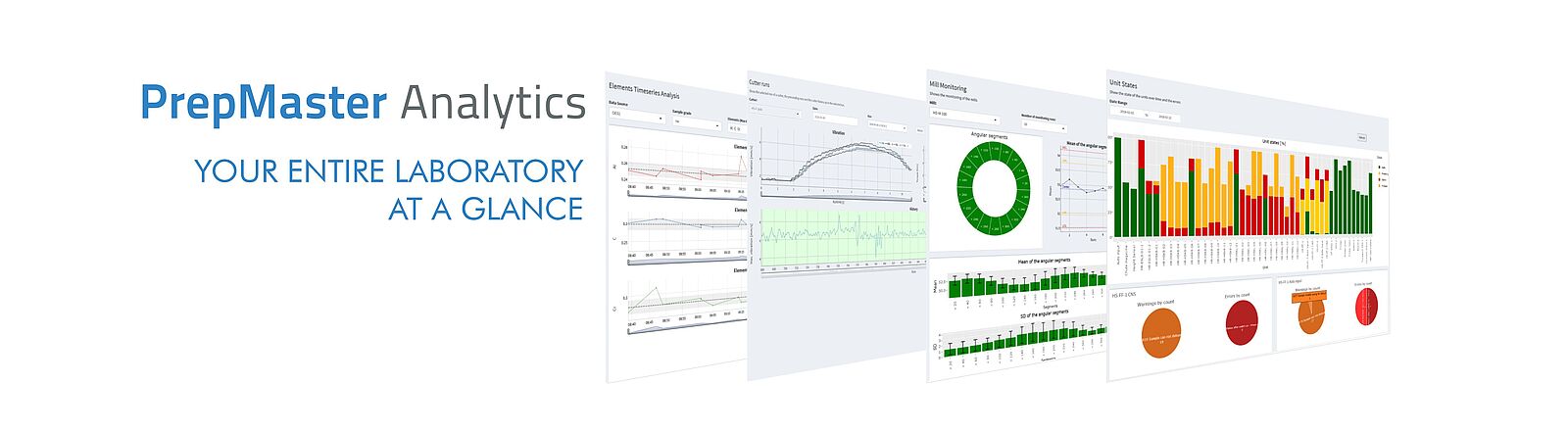

PrepMaster Remote expands PrepMaster from a single-user system to a true multi-user system. PrepMaster Remote enables web-based access to all important operating and monitoring functions of the Scada system without additional maintenance requirements. PrepMaster Remote requires no additional client-side installations and therefore runs independently of platforms and browsers.

System monitoring

PrepMaster Remote provides a quick and clearly structured overview of the functional status of the system. The overview page shows the status of the individual units (Ready, Offline etc.) as icons. The samples in the system are displayed at their current positions as fields with the corresponding identification codes. If there is a robot in the system, it is also shown with the respective position in relation to its rotation axis.

Below the system graphic, all status, warning and alarm messages are displayed in a list together with the respective date and time. This allows a quick overview of the current and past status of the system.

The buttons to the right of the system overview take you to the respective function and overview windows within PrepMaster Remote. The buttons can be used to call up a sample list that contains all current samples at their respective positions. The sample list can also be accessed to delete individual samples from the system or to move them to other positions. The machine list shows all units in the system and their current status.

System control

By clicking on the unit icons and the sample fields, a dialog box can be opened for further operations. In the dialog box for units, buttons can be used to change the state of the unit and, e.g., to switch the machine from automatic to manual mode or to start a synchronization. In addition, commands can be sent within the dialog box to start a program stored in the machine control.

In the sample dialog box, the exact position within the unit is displayed together with the sample ident. Here you also have the option of moving the sample to a designated position within the system with the help of the Move command. Only those positions are displayed that are actually possible and stored in the routing configuration of PrepMaster Core or Entry. After sending the command, you receive immediate feedback whether the sample was moved successfully or not.

Sample registration

With the assistance of the sample registration function, samples can be logged in and introduced into the automated system via input positions and magazines. The operator can select all relevant information for this sample via selection fields including program, input position and sample type. The sample ident is entered and checked using a predefined ident key. The selection fields and identification codes can be set up individually for each system.

For an optimally configured login terminal, PrepMaster Remote can also be delivered on a One Client workstation including all necessary licences, input devices and operating system.