HERZOG proudly announces the delivery of a new laboratory automation for a leading Germany steel plant.

The system consists of two independently working robot cells and is characterized by its special focus on flexibility and modularity. The concept integrates redeveloped as well as tried and trusted equipment.

The slag pneumatic tube carrier is directly forwarded to the slag preparation line where it is opened and discharged without any dust. Opening and emptying within the slag line significantly reduces the load on the robot.

Automatic detection of bad samples and spark position geometry by the built-in camera system allows self-controlled handling and analysis of operational and monitor samples.

Opening of pneumatic tube carriers, alignment, and cooling of steel samples take place in autonomous modules for further robot relief and speeding up process times.

The centrally located milling machine HS-FF 2000 between two robot cells avoids additional transport times in case of sample shift to the other robot circuit.

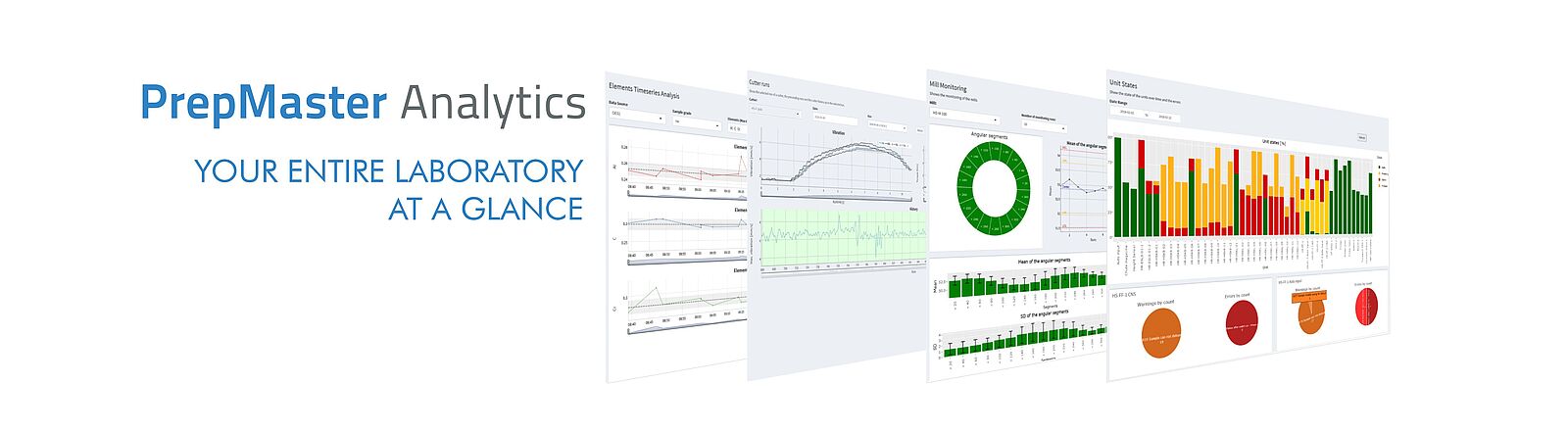

Due to the long-standing cooperation with the leading manufacturers of analyzing instruments HERZOG easily integrates all different components into its Prepmaster SCADA system.

The proven and robust HERZOG technology results in increased reliability and sustainability and eventually to minimized service requirements and downtime.

E-Mail

info(at)herzog-maschinenfabrik.de

Central Office

+49 541 9332-0

Sales Department (technical inquiry)

+ 49 541 9332-50

+ 49 541 9332-68

Marketing

+ 49 541 9332-9981