The company HERZOG was established by Hans-Gottfried Herzog in 1959. The business model was to provide optimal sample preparation for the quality control in the steel industry. At that time, the first commercial x-ray fluorescence spectrometers have been launched leading to significantly accelerated and simplified chemical analyses. Accordingly, HERZOG developed the primal machines for milling, grinding and cutting and sold them to local steel mills. The company rapidly expanded to international markets. As early as in the mid-1960s, majority of machines were already exported to countries inside and outside of Europe. After the death of her husband in 1973, Helga Herzog took over the management and successfully extended the product portfolio to further applications like, e.g., cement and mining. Meanwhile, the wholly family-owned business is operated by the second generation.

HERZOG always geared its solutions towards sustainable industrial developments in order to provide its customers with state-of-the-art technologies. This includes, among others, the development of the automation concepts since the 1970s, the integration of programmable logic controllers since the 1980s and the use of multi-axis robots since the 1990s. Currently, HERZOG focuses on the implementation of smart industry applications for tool condition monitoring and predictive maintenance.

Click through our timeline through past decades and discover the history of our company.

The next generation of the HP-MP has been launched today by HERZOG. The combined mill and press is a mainstay in many industries for preparation of pressed pellets for XRF and XRD analysis. Now, the new version offers even better performance, flexibility and serviceability.

The milling machine HS-F1000 combines innovative technology and full flexibility with a compact and robust design. The main features of the machine are extremely short preparation times, easy automation and highest processing quality of the individual assemblies.

HERZOG is working intensively on the integration of sensory information for tool condition monitoring and predictive maintenance.

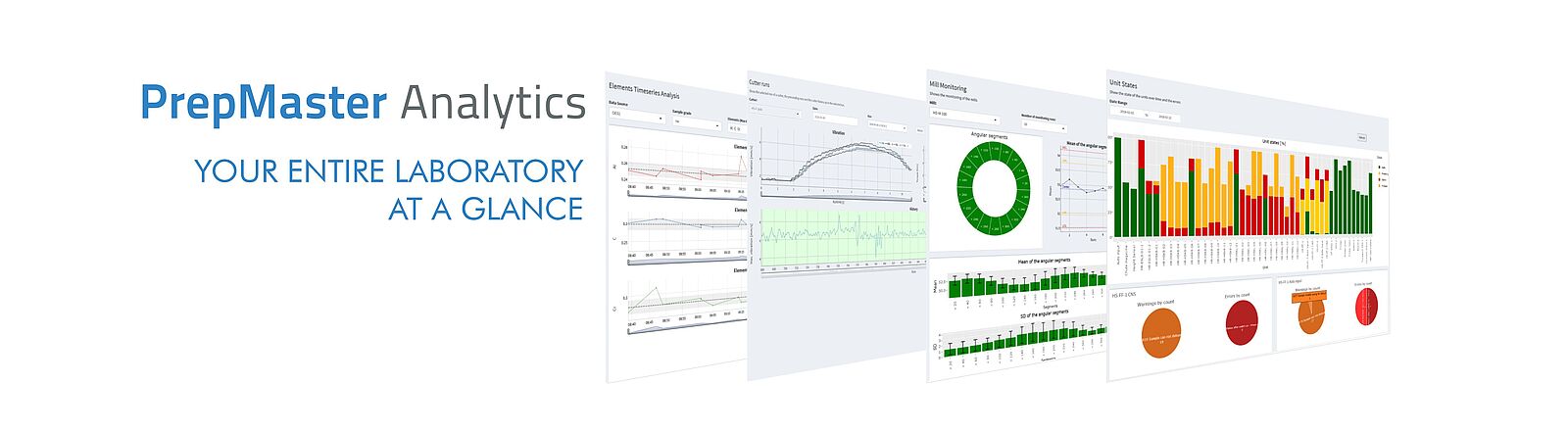

PM Analytics strengthens the PrepMaster family and serves to record, store and analyze analysis, sensor and process information. The aim is to give the customer a comprehensive overview of the status of their automation.

Main focus in the design of new sample preparation devices like, e.g., the milling machine HS-FF is the easy integration into robot automations.

At the beginning of the 2000s, robots were increasingly used for the automation of laboratories for quality control and quality assurance.

Nowadays, robots are standard components that are used for all kinds of applications.

Since the early 2000s, the proprietary SCADA system by Herzog -called PrepMaster is regularly employed for automation control. Since then, the functionality of the PrepMaster has been continuously advanced and extended.

The routine use of programmable logic controller prepared the ground for powerful and flexible automation concepts.

The development of modular design concepts allowed the seamless integration of various automatic components like, e.g., crusher, splitter, mill and press.

Development of semi- and fully automatic units for fusion of oxidic samples. According to the equipment variant, various options were available including magazine function, dosing of sample and flux as well as cleaning.

The design department of Herzog is of key importance for the production of super-quality machines and automations. Our highly qualified engineers have always made use of state-of-the-art technologies. At the beginning of the 1980s, all design drawings were prepared manually. Only few years later, Herzog was among the first companies to introduce commercial CAD systems.

Nowadays, CAD is standard equipment in every design department.

Automatic sample milling machine HMF-

Fully-automatic system for machining spectroscopic samples of non-ferrous metals.

The HMF had two modes of milling with programmable spindle speeds and feed rates as well as automatic sample magazines or conveyors.

Semi-automatic pulverizing mill HSM-F for batch-processing of granular sample material. The machine was completely enclosed and sound-insulated. The machine was equipped with a fully-automatic dosing unit for sample material and grinding aid.

Manual belt grinding machine HNB 1500-

Sample preparation for spectroscopic analysis using wet and dry sanding.

Milling machine HFS 120-2 with two milling heads-

Miller with swivel support especially developed for preparation of samples for spectroscopic analysis. The machine enabled a reproducible sample surface for spark spectroscopy and the production of chips for wet chemical analysis.

The establishment of Herzog Maschinenfabrik by Hans Gottfried Herzog was closely related to the development of the first commercial X-ray fluorescence analyzers. Initially, Herzog produced cutting and grinding machines for solid samples. Later, sample preparation devices for powder material were developed as well.